EPD - Settecento

1. General Information

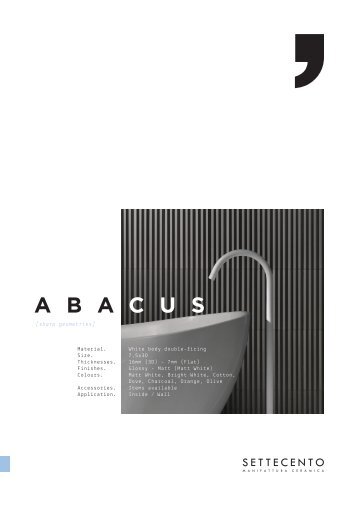

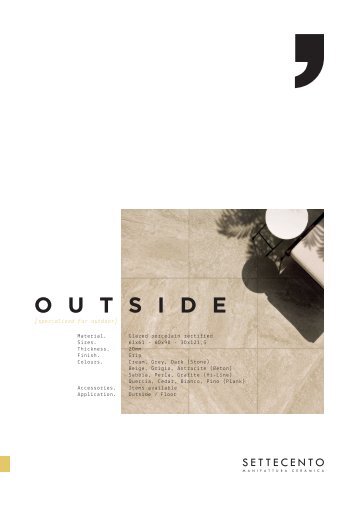

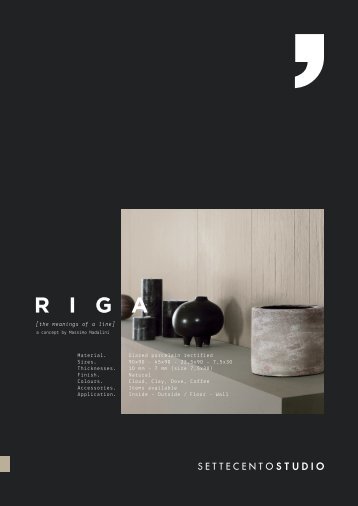

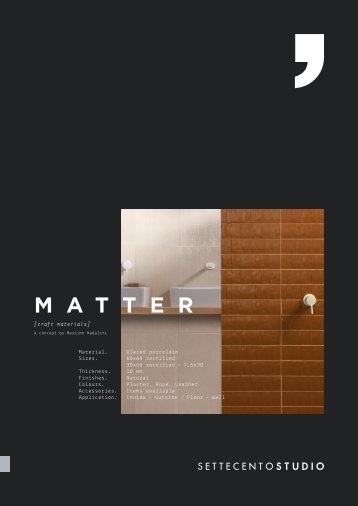

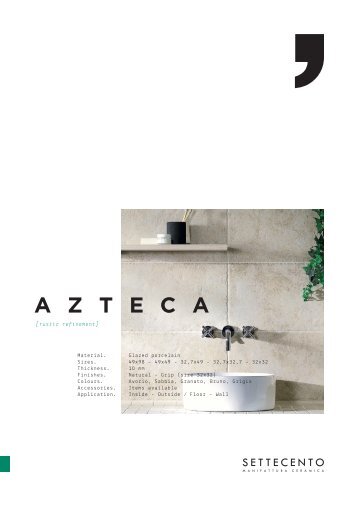

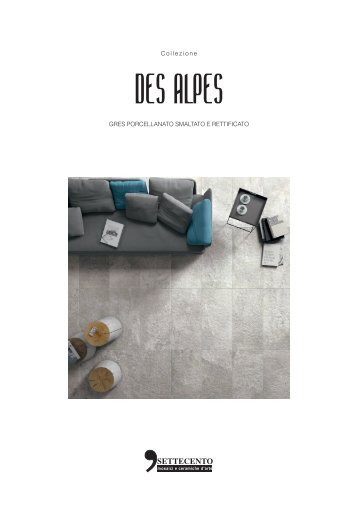

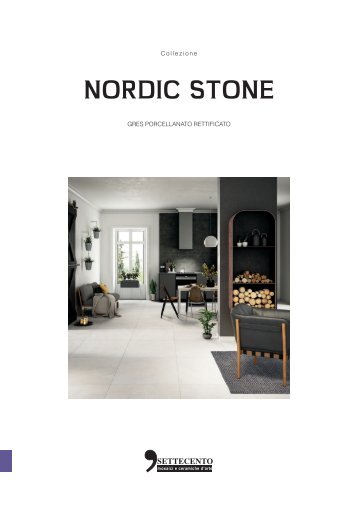

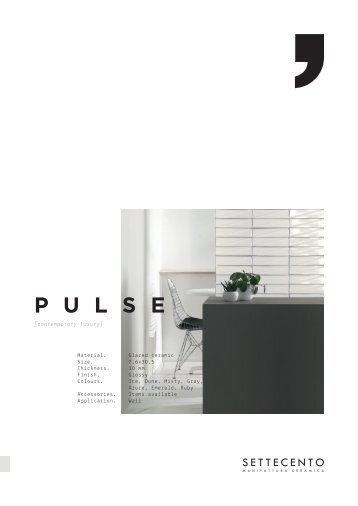

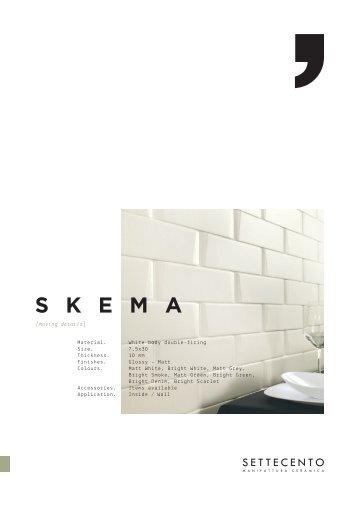

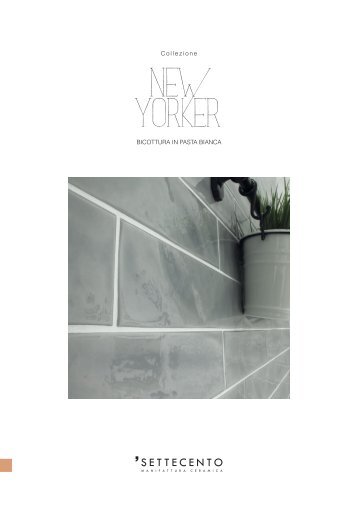

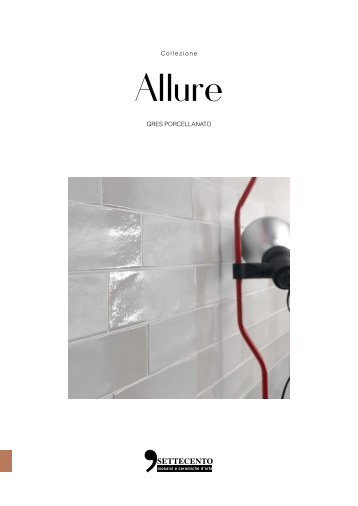

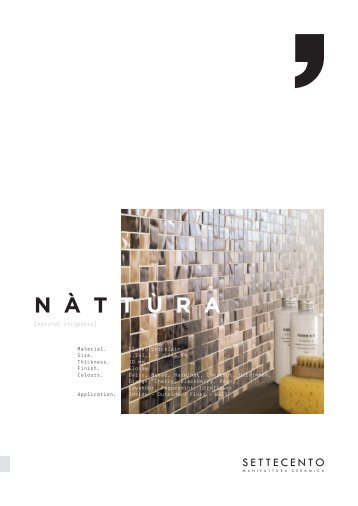

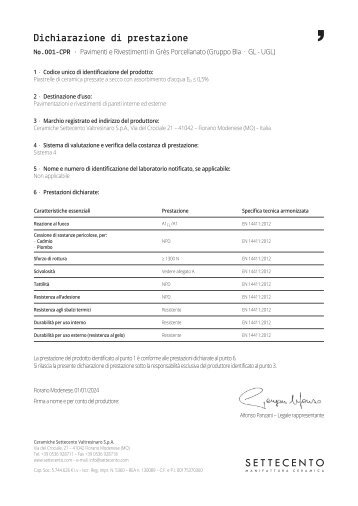

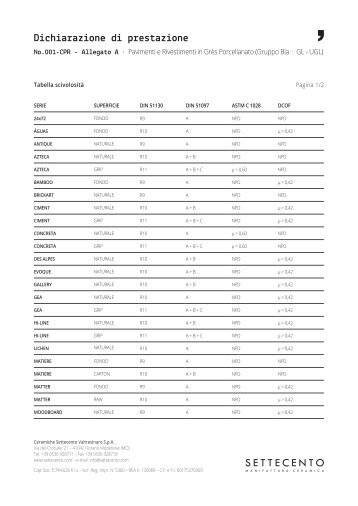

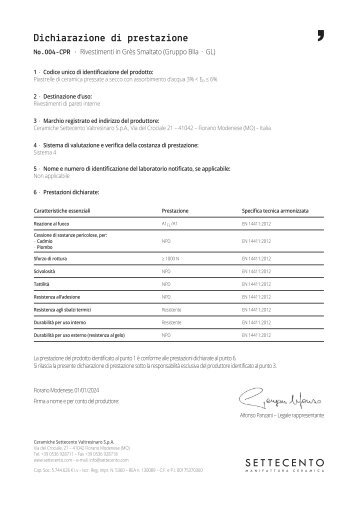

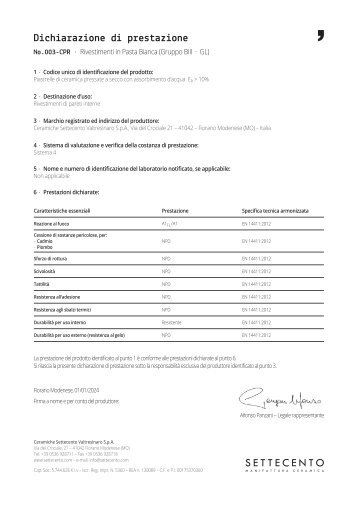

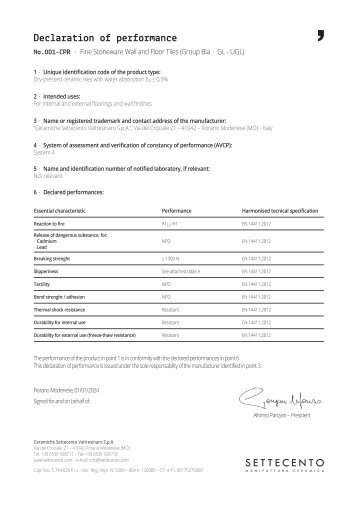

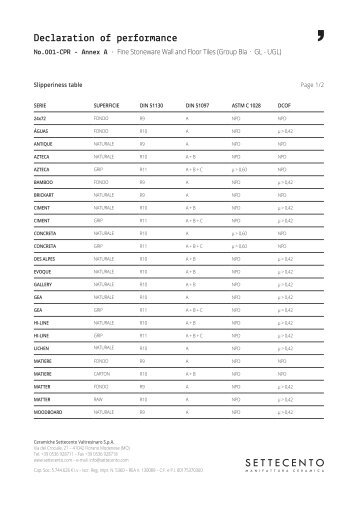

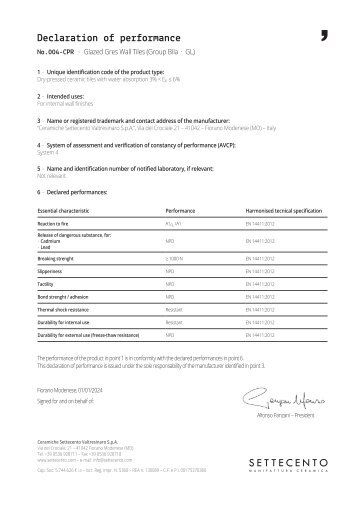

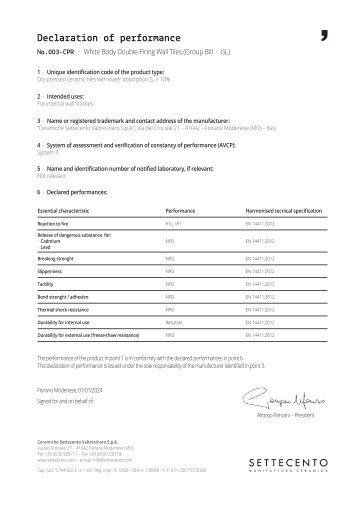

1. General Information Confindustria Ceramica Programme holder IBU – Institut Bauen und Umwelt e.V. Hegelplatz 1 10117 Berlin Germany Declaration number EPD-COI-20220297-ICG1-EN This declaration is based on the product category rules: Ceramic tiles and panels, 09.2022 (PCR checked and approved by the SVR) Issue date 04/01/2023 Valid to 03/01/2028 Italian Ceramic Tiles Owner of the declaration Confindustria Ceramica, Viale Monte Santo 40 41049, Sassuolo, Modena Italy Declared product / declared unit 1 m 2 of installed ceramic tile (average) Scope: This document refers to an average installed ceramic tile product manufactured by Confindustria Ceramica's member companies. This verified EPD is an update of the previous version published in 2016. Part of the LCA data collected in 2014 have been updated within the members' companies of the association. This study has involved, as primary data 74 companies and 87 plants, that represent 82,6 % of the Italian ceramic tiles production. The final results are representative of Confindustria Ceramica's member companies. Dipl. Ing. Hans Peters (chairman of Institut Bauen und Umwelt e.V.) The owner of the declaration shall be liable for the underlying information and evidence; the IBU shall not be liable with respect to manufacturer information, life cycle assessment data and evidences. The EPD was created according to the specifications of EN 15804+A2. In the following, the standard will be simplified as EN 15804. Verification The standard EN 15804 serves as the core PCR Independent verification of the declaration and data according to ISO 14025:2011 internally x externally Dr. Alexander Röder (Managing Director Institut Bauen und Umwelt e.V.)) Matthias Schulz (Independent verifier) 2. Product 2.1 Product description/Product definition Ceramic tiles, produced by Confindustria Ceramica's member companies are shaped mainly by dry pressing (but also by extrusion), starting from natural raw materials such as clay, feldspar, sand and kaolin. The main type of ceramic tiles is porcelain stoneware, characterized by a very compact structure and high performances. Other types include single-fired tiles, like monoporosa, double-fired tiles, etc. For this study an average ceramic tile product, representative of the whole production of Confindustria Ceramica’s member companies, has been identified and adopted. For the placing on the market of the product in the European Union/European Free Trade Association (EU/EFTA) (with the exception of Switzerland) Regulation (EU) No. 305/2011 (CPR) applies. The product needs a declaration of performance taking into consideration EN 14411: 2012 Ceramic tiles - Definitions, classification, characteristics, evaluation of conformity and marking - and the CE-marking. For the application and use the respective national provisions apply. 2.2 Application The ceramic tiles under study are intended and applied for both floor and wall coverings, installed both in internal and external environments, for residential, commercial and institutional use. 2.3 Technical Data Ceramic tiles produced by Confindustria Ceramica’s member companies conform to the following standards and specifications. According to EN 14411 in Europe and ISO 13006 in the rest of the world ceramic tiles are classified into five main types based on shaping methods (A = Extrusion, B: Dry pressing) and water absorption level. 2 Environmental Product Declaration Confindustria Ceramica – Italian Ceramic Tiles

Ceramic tiles with the lowest water absorption level (≤ 0.5%) can be designated as porcelain tiles (impervious tiles) Mosaic and trim units are included. Constructional data Name Value Unit Water absorption acc. to ISO 10545-3 0.0 - 20 % Modulus of rupture acc. to ISO 10545- 4 Breaking strength acc. to ISO 10545-4 8 - 35 (min) 200 - 1300 (min) Resistance to surface ware – Glazed tiles acc. to ISO 10545-7 0 - 5 Coefficient of linear thermal expansion 9 E10-6 acc. to ISO 10545-8 (max) Thermal shock resistance acc. to ISO Resistan 10545-9 t Crazing resistance acc. to ISO 10545- Resistan 11 t Frost resistance acc. to ISO 10545-12 Declared (if available) value Non-slip propertie (Refer to national Declared regulation) value Test Impact resistance acc. to ISO 10545-5 method available Reaction to fire NO testing (CWT) A1-A1FL Chemical resistance acc. to ISO 10545-13 Resistance to staining acc. to ISO 10545-14 Release of lead and cadmium acc. to ISO 10545-15 Moisture expansion acc. to /ISO 10545-10/ Resistance to deep abrasion - acc. Unglazed tiles to ISO 10545-6 A - C GL – Min Class 3 UGL – Dec. Value If required Declared Value 2365 for A, 540 for B N/mm^2 N Abrasio n Class 1/K nm^3 · Natural pigments · Frits Main auxiliary additives: · Dispersant · Binder · Fluidifying agents . Pigments This product contains substances listed in the candidate list of substances of very high concern (REACH Regulation, date: 10.06.2022) exceeding 0.1 percentage by mass: no This product contains other Carcinogenic, Mutagenic,Reprotoxic (CMR) substances in categories 1A or 1B which are not on the candidate list, exceeding 0.1 percentage by mass: no Biocide products were added to this construction product or it has been treated with biocide products (this then concerns a treated product as defined by the (EU) Ordinance on Biocide Products No. 528/2012): no 2.6 Manufacture The typical manufacturing process of the ceramic tile object of this EPD is represented and described below. - Performance data of the product in accordance with the declaration of performance with respect to its essential characteristics according to EN 14411: 2012 Ceramic tiles - Definitions, classification, characteristics, evaluation of conformity and marking. - Voluntary data: EN 14411: 2016 Ceramic tiles - Definition, classification, characteristics, assessment and verification of constancy of performance and marking (not part of CE-marking). 2.4 Delivery status The measurements of products can vary between different formats, thicknesses range from 3 mm (for ultra-thin tiles) to 30 mm (for thickened tiles). 2.5 Base materials/Ancillary materials Main raw materials for ceramic tile: · Clay 42 % · Sand 13 % · Feldspar 35 % · Rhyolite 4 % Main glaze components: · Clay powder · Quartz · Alumina The required composition of raw materials, including also recycled wastes, is mixed and grinded in mills, either in a wet or a dry process. In the wet process, the slurry produced (with around 25-30 % water) is treated in spray driers that use thermal energy from natural gas and high air pressure in order to produce a dry powder with spherical granules of appropriate size distribution, ready to be pressed. In the drying process the production of energy via cogeneration is a widespread practice. In the dry process, without water, no spray driers are used. Ceramic tiles are generally formed by dry pressing, using special moulds (isostatic pressing). At present new forming techniques have been developed in particular for thin and large size tiles, using special tape compaction procedures. The required formats are obtained by cutting the initial slabs after compaction. Glazing and decoration are performed on dried tile surfaces. Both wet and dry application techniques can be used. Digital glazing and decoration techniques have been introduced and adopted in the ceramic tile industry, and are at the base of very special ceramic tile surfaces. 3 Environmental Product Declaration Confindustria Ceramica – Italian Ceramic Tiles

- Page 1: ENVIRONMENTAL PRODUCT DECLARATION a

- Page 5 and 6: 3.1 Declared Unit The declared unit

- Page 7 and 8: C1: This module considers the use o

- Page 9 and 10: RESULTS OF THE LCA - INDICATORS TO

- Page 11 and 12: UNI EN ISO 10545-3:2018, Ceramic ti

- Page 13 and 14: LA FABBRICA SPA LAMINAM SPA MARAZZI

Inappropriate

Loading...

Mail this publication

Loading...

Embed

Loading...